The Brightin Centre:

Boiler Plant and Controls Replacement

The Brighton Centre is a Conference and exhibition centre Located in Brighton and is the largest of its kind in Southern England and was opened in 1977.

The site is located on Kings Road, Brighton BN1 2GR

The works were confined to the 4th. & 5th. Floors and the roof above, they included the following:

The original boiler (no.2) has reached the end of its life and was inefficient and in need of urgent replacement, the works included.

– Removal and adaptation of existing services

– Extension Of Existing Gas Pipework

– Removal of Existing Boiler

– Installation of Ne ‘High Efficiency’ boiler and flue

– Modifications to existing pipework services

– Installation of new control Panel

– Scaffolding

– Associated builders works

Due to the activities of the Centre and the position of the roof top plant room the project took very intensive/thoughtful planning to achieve a successful project.

This included numerous risk assessments and method statements, and daily communication with the building maintenance staff.

Edgar & Wood employed specialist contractors to dismantle the existing boiler and flue system. The redundant plant was carefully dismantled and taken down to ground level via tradesman lifts and complex scaffold structures, to a secure storage area, and then sent to a recycling centre.

The new boiler installation consisted of a Remeha Gas 320 Ace 650 Kw RHC linked to a Remeha gas 620 Ace 1300 Kw, giving a new total boiler output of 1950 Kw.

On completion the new boilers were fully commissioned by the manufacturers.

The new boiler has outstanding efficiencies (99.3% gross efficiency) making the Remeha Gas Ace one of the most efficient commercial boilers across Europe, giving:-

– Exceptional Reliability

– Fully Modulating

– Maximum BREEAM points for low emissions.

– Future Proof

The complex installation was carried out by Edgar & Wood Ltd.’s ‘Gas Safe’ engineers.

The controls upgrades were installed and commissioned by ‘Honeywell’.

To minimise any downtime of heating / hot water E&W’s lead engineer completed a

follow-up preinstallation site visit prior to the spring installation to fully determine the best approach for the switch over to include the decommissioning and removal of the existing boiler, pipework and flue alterations and installation of the commercial boiler.

All works were completed to schedule and with Gas Safe and NICEIC electrical commissioning certification issued upon project completion.

The project was completed successfully and within time and contract dates for Brighton & Hove City Council (Framework)

Hove Park Junior School:

Boiler Plant, Heating and Controls Replacement

Hove Park Junior School is located in Portland Road, Hove East Sussex, BN3 5JA

The works were confined to all internal areas of the school, the work were carried out during normal school terms and available holiday periods.

Edgar and Wood Ltd. carried out the project as ‘Principle Contractor’.

The original boiler plant and heating distribution had reached the end of its life and was inefficient and in need of urgent replacement, the works included:

– Removal and Installation of the Heating Distribution system

– Extension Of Existing Gas Pipework

– Removal of Existing Boilers

– Installation of Ne ‘High Efficiency’ boilers and flue

– Modifications to existing pipework services

– Installation of new control Panel

– Installation of new heat emitters inc. radiant panels

– Associated builders works

Due to the activities of the school and the works being carried out during ‘normal’ and ‘out of hours’ the project took very intensive/thoughtful planning to achieve a successful project.

This included numerous risk assessments and method statements, and daily communication with the building maintenance staff.

Our contracts manager and site foreman had to plan and produce complex programmes to ensure the project kept the programme and did not affect the everyday activities of the school.

This ensured the safety of the staff and pupils at all times, complex RAMS were produced by our H&S consultant to cover all procedures of the works.

Edgar & Wood employed specialist contractors to dismantle the existing boilers and flue system, The redundant plant was carefully dismantled and taken to a secure storage area, and then sent to a recycling center. Following the removals the new plant was installed by our experienced ‘gas safe’ engineers.

A Full R&D Asbestos survey was carried out prior to the works starting and any asbestos indetified or removed by one of our specialist contractors.

The internal heating distribution was removed and re-installed by our experienced engineers. The new boiler installation consisted of 4 Remeha Gas 210 Eco 200 kw giving a new total boiler output of 800 Kw. The new heating distribution consisted of Radiators, Fan Convector’s and Radiant Panels. On completion the new boilers were fully commissioned by the manufacturers.

The new boiler has outstanding efficiencies (99.3% gross efficiency) making the Remeha Gas 210 ECO is one of the most efficient commercial boilers across Europe, giving:

– Exceptional Reliability

– Fully Modulating

– Maximum BREEAM points for low emissions.

– Future Proof

The complex installation was carried out by Edgar & Wood Ltd’s ‘Gas Safe’ engineers.

The controls upgrades were installed and commissioned by ‘Edwards Modular Controls’.

To minimise any downtime of heating / hot water E&W’s lead engineer completed a follow-up preinstallation site visit prior to the summer installation to fully determine the best approach for the switch over to include the decommissioning and removal of the existing boiler, pipework and flue alterations and installation of the commercial boilers. A Temporary boiler plant was installed to ensure there were failures of the schools heating during the winter term periods.

All works were completed to schedule and with Gas Safe and NICEIC electrical commissioning certification issued upon project completion.

The project was completed successfully and within time and contract dates for Brighton & Hove City Council

Ninfield Primary School East Sussex

Ninfield primary school is in Ninfield village within East Sussex, TN33 9JW.

The site consists of the main building dated from 1854 and the recent extension of two classrooms in 2019.

The works undertaken were within the main building of this single storey school that encompasses a total floor area of 621 m2.

The original oil fired heating system was extremely inefficient and no longer fit for purpose, the original part of the building due to its age was also poorly insulated.

The aim of the project was to improve the buildings efficiency and reduce its ‘Carbon Footprint’

Ninfield school was one of the first ESCC properties to install ‘Air Source Heat Pumps’ helping the schools transition to green energy.

The new system maintains a comfortable temperature throughout the school, whilst being as energy-efficient and carbon neutral as possible.

The project was to de-commission the existing old oil fired plant, and remove the existing redundant pipework and materials, and to install a new low carbon heating system.

The design included new a BMS control system, with multiple heating zones for greater control and efficiency.

The old HWS cylinder was removed from the plant room and new ‘Point of Use. Electric water heaters were installed throughout the school. Disruption to the school’s everyday activities, pupil attendance and the down time of the heating system were paramount factors during the works.

But with careful planning and communication with the stakeholders this was achieved with minimal disruption.

The new ‘Daikin’ ASHP’s incorporating 2 x 50Kw units and new pipework distribution system which supplies the school, are installed externally adjacent to the existing plant room , which meant minimal internal and external disruption to the main public areas was minimalised.

To help the school reach its goal of zero carbon emissions, the works also included the replacement of the existing lighting throughout the school with new LED lighting, including emergency lights where required.

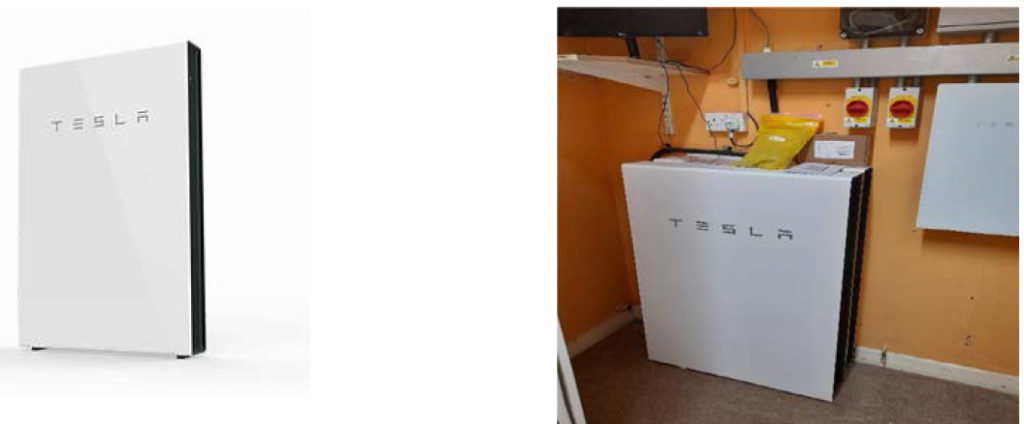

The works also included a new battery storage gateway which can be recharged on low cost electricity and in the future used with a solar PV system.

The ‘Tessla Powerwall 2’ is a rechargeable Lithium-ion battery storage system that can be used to power the building during the evenings or poor weather conditions.

The storage system consists of 2 13.5 kWh capacity batteries.

– 5 Kw power .

– 90% round trip efficiency

– 10 year warranty

In the existing original part of the school the existing external walls were re-insulated to increase the efficiency of the building. The project has resulted in an approximate saving of between 15 & 35 % on energy bills. An R&D survey was carried out site specific to the project prior to any works taken place.

A specialist sub-contractor was appointed to remove/clean the contaminated areas within the plant room as part of the project, including the removal of the plant room ceiling.

All the newly installed main items of plant were commissioned by the manufacturer to ‘ Rubber Stamp’ the client’s warranties.

A full maintenance inspection was carried out at the end of the 12 months defects period. The project was completed within the contract dates and on time. The Project was carried out for East Sussex County Council (Framework) and completed within the contract budget.

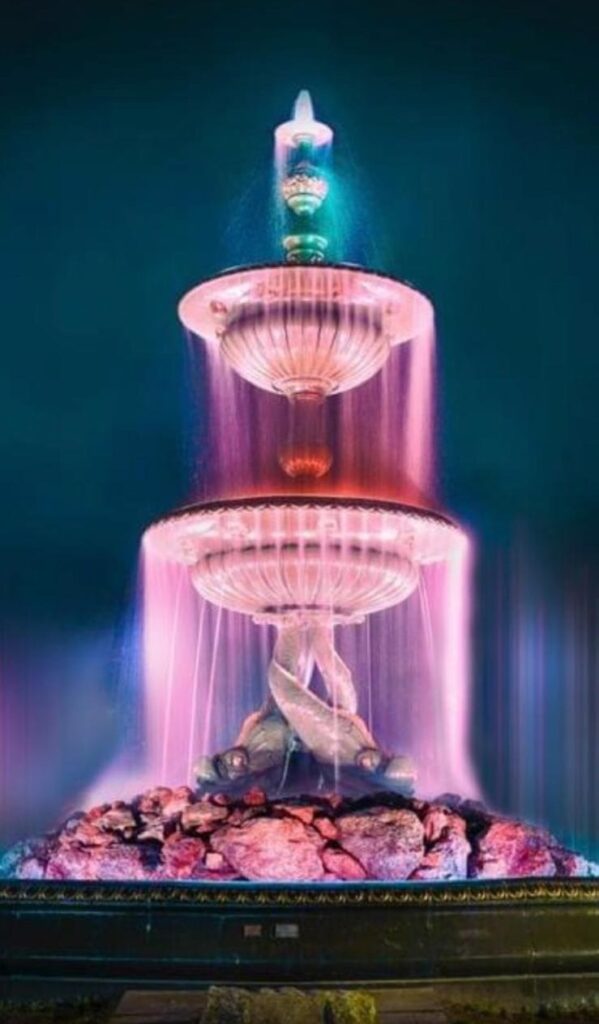

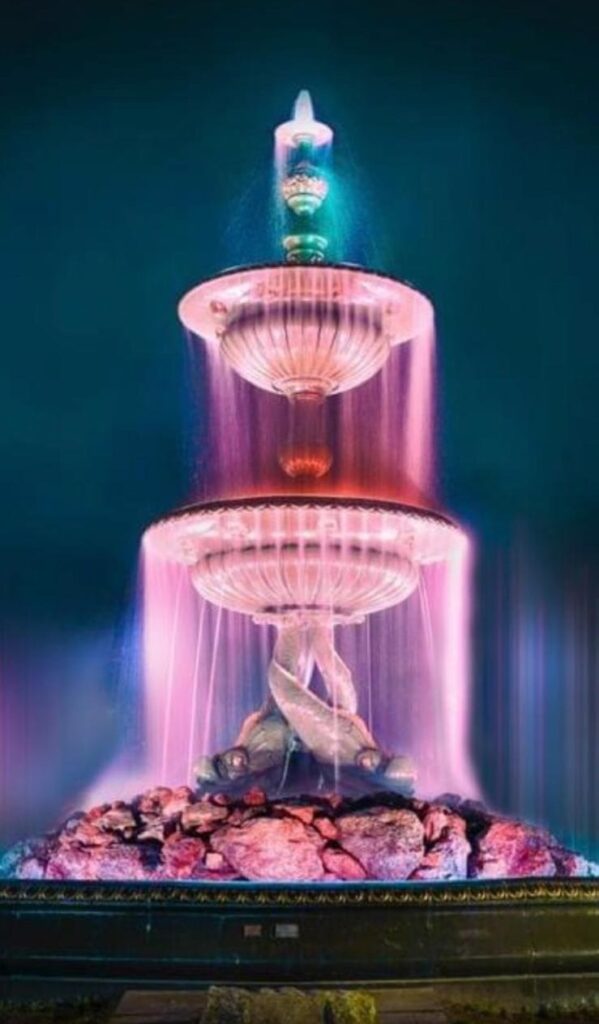

The Victoria Fountain

Old Steine Gardens:

Restoration

Edgar and Wood Mechanical Services Ltd were contracted to oversee the restoration of the historic Victoria Fountain which was situated in the Old Steine Gardens.

The 32ft fountain was disassembled and transported to workshops in Leicester, where it underwent a complete restoration.

The work had to be carried out due significant and complex structural problems that were discovered.

The large, cast-iron structure was blasted ready for inspection and then the welding work started. The project used specialist contractors working on the metalwork, water features and lighting.

While the fountain was being restored, a complete new reinforced concrete base was built on the original site, providing a solid, secure and level base, for the restored structure.

The fountain was finally fixed back into place fully restored.